Grinding wheel

standard sizes and specs

| Standard | Bond designation | Structure | Size |

|---|---|---|---|

| GC 1200 G | Resinoid Grinding Wheel | 7 | 406 × 102 × 127 |

| GC 2000 F(-) | Resinoid Grinding Wheel | 7 | 355 × 100 × 127 |

| GC 1000 I | Resinoid Grinding Wheel | 7 | 405 × 100 × 127 |

| GC 800 L | Resinoid Grinding Wheel | 6 | 100 × 50 × 20 |

| GC 600 J | Resinoid Grinding Wheel | 1 | 200 × 20 × 50 |

| GC 600 J | Resinoid Grinding Wheel | 1 | 200 × 20 × 31.75 |

| GC 600 L | Resinoid Grinding Wheel | 1 | 200 × 10 × 31.75 |

| GC 1000 J | Resinoid Grinding Wheel | 6 | 100 × 50 × 20 |

| GC 600 L | BResinoid Grinding Wheel | 6 | 100 × 50 × 20 |

| GC 1000 F | Resinoid Grinding Wheel | 7 | 450 × 203 × 304.8 |

| GC 1000 G(+) | Resinoid Grinding Wheel | 7 | 508 × 102 × 203.2 |

| GC 1000 L | Resinoid Grinding Wheel | 6 | 100 × 50 × 20 |

| GC 1000 G | Resinoid Grinding Wheel | 7 | 406 × 102 × 127 |

| GC 1500 G | Resinoid Grinding Wheel | 7 | 450 × 100 × 203.2 |

| GC 2000 G | Resinoid Grinding Wheel | 7 | 450 × 100 × 203.2 |

| SA/PA 120 I | Vitrified Grinding Wheel | 1 | 200 × 20 × 50 |

| SA/PA 120 I | Vitrified Grinding Wheel | 1 | 200 × 18 × 50 |

| SA/PA 120 I | Vitrified Grinding Wheel | 1 | 200 × 19 × 50 |

| SA/PA 120 I | Vitrified Grinding Wheel | 1 | 200 × 30 × 50 |

| SA/PA 120 I | Vitrified Grinding Wheel | 1 | 200 × 25 × 50 |

| SA/PA 120 I | Vitrified Grinding Wheel | 1 | 200 × 10 × 50 |

◆

Improve efficiency of grinding and reduce

cost by curb the generation of burrs.

The major issues of needle grinding are occurrence of burrs and lifetime of grinding wheels. Many grinding wheel makers try to improve their wheel’s lifetime by increase hardness. However, it usually generate many burrs when proceed the grinding to the first bevel.

Our manufacturer recognize that solving these contradictory issues simultaneously is the most

important task imposed on the grinding wheel manufacturer.

We have

always been aware of the problem and have been working on the development of

grinding wheels for injection needles.

◆We improved lifetime of our grinding wheel by using the new blinder

We newly adopted an ester binder for the

production of grinding wheels.

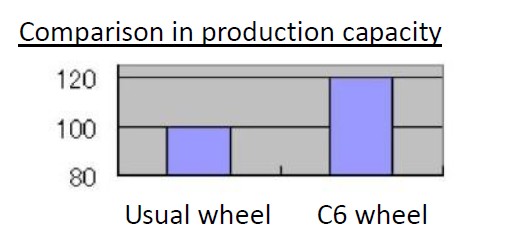

Comparisons with our previous models have

resulted in a 20% increase in its life.

Furthermore,

we have received high marks in the running test at major users and it has been

adopted.

◆Reducing the generation of burrs

Usually it is thought that grinding by ester

binder wheel is difficult. However, Our company manufacture the grinding wheels

with our own know-how.

Reducing the generation of burrs makes it

possible to save the time of burr removing work and reduce the defective rate.

◆Other availabilities and our activities

① Tapered grinding wheel

② Provide grinding wheel with flange

③ ISO9001

④ Wealth knowledge in grinding wheel producing to accommodate each customer needs.

◆ Particle size

#320

#400

#600

#800

#1000

#1200

#1500

#2000

◆ Hardness

F~J(Grade)

◆ Structure

Type.1

Type.5

Type.7

*Flange can be attached to a grinding wheel

Cutting wheel

Cutting Wheel Specification Table

standard sizes

Thickness O.D. |

0.3mm | 0.4mm | 0.5mm | 0.6mm | 0.7mm | 0.8mm | 0.9mm | 1.0mm | 1.2mm |

| 10mm | |||||||||

| 50mm | |||||||||

| 75mm | |||||||||

| 100mm | |||||||||

| 125mm | |||||||||

| 150mm | |||||||||

| 180mm | |||||||||

| 205mm | |||||||||

| Grindingmaterial Graindegree # |

240 | 180 | 80 | ||||||

| Thickness error margin | ± 0.02 | ± 0.02 | ± 0.05 | ||||||

The sizes other than a standard size are manufactured by hope.

Glass beads

Available sizes for needle polithing

| Item Code | Particle Size | ||||

| GB106DE | 125μm Residual 0% |

125~106μm Less than 10% |

106~53μm More than 80% |

53μm Pass Less than 10% |

|

| GB252E | 106μm Residual 0% |

106~75μm Less than 10% |

75~45μm More than 80% |

45μm Pass Less than 10% |

|

| GB075CT | 90μm Residual 0% |

90~75μm Less than 10% |

75~45μm More than 60% |

45μm Pass Less than 30% |

|

| GB053BE | 75μm Residual 0% |

75~63μm Less than 10% |

38μm Pass Less than 20% |

||

| GB053BT | 75μm Residual 0% |

63μm Residual Less than 1% |

63~53μm Less than 20% |

53~38μm 45~85% |

38μm Pass 15~35% |

| GB241E | 63μm Residual 0% |

63~53μm Less than 20% |

53~38μm More than 60% |

38μm Pass Less than 20% |

|

| GB045AE | 63μm Residual 0% |

45~38μm More than 30% |

38μm Pass Less than 70% |

||

| J-400T | 63μm Residual 0% |

45μm Pass More than 80% |

|||

| GB800F | 53μm Residual 0% |

45μm Residual Less than 10% |

38μm Residual Less than 35% |

38μm Pass More than 65% |

10μm Pass Less than 2% |

| J-800T | 45μm Residual 0% |

38μm Pass More than 80% |

|||

| EJ-1200T | 32μm Residual 0% |

20 μm Pass More than 80% |

|||

◆上限残留0.4%以下は、残留0%とみなします。 Less than 0.4% which is upper limit is considered as residual 0%

◆上記ガラスビーズには、流動性改善処理(表面コーティング)が施されております。 Surface treatment has been done on the glass beads.